About IPMA

IPMA was established in 1951 for growth of Indian pump industry.

RELEVANCE OF PUMPS IN THE GROWTH OF INDIAN ECONOMY

In the context of agricultural sector, it is pertinent to note that much of the credit of India’s self-sufficiency in food does credit also to Indian Pump Industry.

In the context of the sector of infrastructure, utilities and services, it may be noted that Indian pumps have been servicing the needs of urban water supply wholly indigenously since decades. Even large irrigation and water supply project of gigantic scales are being executed wholly indigenously by Indian Pump Industry.

In the context of industrial sector, capabilities and contributions can be cited simply by the fact that almost all pumps in very critical services as in nuclear power generation are designed and made within Indian pump industry.

SIZE AND COMPOSITION OF INDIAN PUMP INDUSTRY

It is estimated that the production of pumps in the country is presently of the order of Rs. 20,000 crores, (US$ 2994 million), produced by some 800 odd manufacturers of large, medium and small scales. The pump manufacturers are able to meet most of the domestic market demand and they also export pumps worth Rs. 1200 crores in 2014-15.

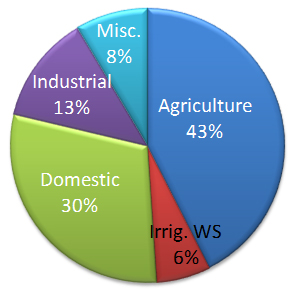

SECTORWISE DEMAND OF PUMPS IN INDIA

MARKET-POTENTIAL AND MARKET TRENDS

As can be seen, market potential and growth in demand for pumps depends on the growth in sectors using pumps. Market demand in different sectors is itself influenced by various related factors. For example, in India demand for pumps for agriculture is substantially influenced by monsoon. Projects like equitable distribution of water from regions of abundance of water to regions deficient in water or projects for interlinking of rivers would cause a big boost in demand for pumps for such infrastructural activity.

The pattern of demand will be different in different countries. For example, in desert regions, the demand for pumps for agriculture will be minimal. Information and study of the demand pattern in different countries will be necessary for an exporter. Information on nature and state of economy in different countries can be studied from the website of World Bank.

PUMPS AND MARKET-STYLES

Among “machineries”, pumps are said to be produced and used in largest numbers, second only to electric motors. Pumps are both power-driven and manually operated.

The market for Pumps operates in various fashions –

• Bare-shaft pumps to be assembled by the trader or end-user with motor or driver from his stock

• Pump complete with driver, either as a monoset or mounted and aligned on a base plate and maybe, also complete with switch-gear and controller, etc.

• Pump as a part of a packaged system. For example an off-shore oil rig will have a variety of pumps on it. Or an onboard desalination or water-purification system on ocean-going ships has relevant pumps in the packaged system

• Kits and/or components for the trader or buyer to assemble them into a pump later. People can be outsourcing kits or components for their manufacture of pumps.

There is another way of looking at Market styles and Pump types.

• Pumps for agriculture and domestic usage are primarily sold through dealers and stockiest.

• Pumps for industrial purposes may be sold through agents, dealers and stockiest. But pumps for offensive services would often need special materials of construction and would be made against orders. Even enquiries from pumps from the industrial sector would be often elaborate and would merit detailed technical scrutiny. Manufacturers would get involved right from beginning of the project.

• Requirements for pumps in the industrial sectors would be either for replacement or for new project. There is a good requirement also for replacement spares. These may be catered to by dealers and stockiest.

• Because pumps in industrial sector are generally run for long, continuous periods, the users would also need after-sales service support from the manufacturers. For marketing pumps for industrial sector in the global markets, pump-manufacturers may need to establish their own service centers or have competent representatives.

• Requirements for pumps for large projects would also be handled by the manufacturers directly.

ROLE OF INDIAN PUMP INDUSTRY IN THE SECTOR OF AGRICULTURE

When India achieved independence, electricity was available insufficiently. Agricultural pumps in those times were prominently engine-driven. Even today, engine-driven pumps come handy to farmers, in situations of insufficient power-supply and in remote places, where electricity has not yet reached.

With spread of electricity, electric pumpsets, especially of monoset variety (IS-9079) became popular. Propelled by commissioning of major irrigation projects, growth in agriculture soon made the country self-sufficient in food.

Growth in agriculture so much overtook the growth in irrigation, that surface waters were no more adequate. That set the trend for exploring ground waters. This prompted growth in manufacture of bore well submersible pumpsets (IS-8034).

Hand pumps (IS-9301) and centrifugal jet pumps (IS 12225) were competing with submersible pumpsets until ground water level had not depleted very low.

Now submersible pumps have caught so much fancy with farmers and with pump-users in general, that people prefer to use them even where water level is not deep. The appealing features are freedom from priming the pump at every instance of loss of prime and security against theft. Such fancy for submersible pumps prompted the development of also the Open Well Submersible Pumps (IS-14220).

ROLE OF INDIAN STANDARDS

The mention above, of numbers of IS standards for different types of agricultural pumps should in itself become a point to note.

Bureau of Indian Standards (BIS), formerly Indian Standards Institution (ISI), has had a Technical Committee for pumps almost since its inception.

However, it is important to note, especially in the context of agricultural pumps, that Indian Standards have addressed issues of national concern. Growth in agriculture and growth in use of agricultural pumps started putting heavy strain on power and fuel. Norms for minimum efficiency were incorporated first time in 1979 in Indian standards on agricultural pumps. This aspect is so unique that even today no International standard specifies norms for minimum efficiency. Only in Hydraulic Institute standards, there is a monogram on “Estimating efficiency of centrifugal pumps”. The monogram is primarily a guideline and is not a norm for mandatory compliance.

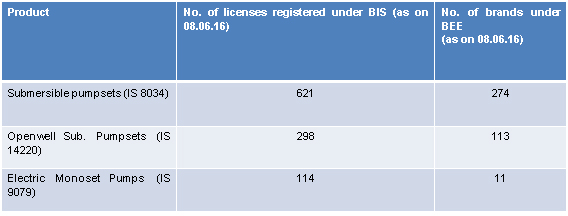

Apart from developing standards BIS operates scheme for licensing use of ISI mark. Since years, tenders of Government departments have been specifying pumps to have ISI mark. This inherently means compliance with the norms for minimum efficiency.

Since 2009, the Bureau of Energy Efficiency , Ministry of Power, Govt. of India has started “Standard and Labelling Scheme” for agriculture pumps.

STAR RATING CHART TO BE ADDED.

Importance of pumping system to be proper, so that the consumption of power will be optimal, was realized long time back. It was in 1979 that IS-10804 standard for “Recommended Agricultural Pumping System” was developed. Although the title of the standard read as “Recommended”, NABARD made it mandatory for its refinance of loans afforded to farmers for the pumps.

International leaderships in pump technology. All these technologies have been in India since 1970.

NOTEWORTHY FEATURES OF INDIAN PUMP INDUSTRY

Indian market for Industrial Pumps and Systems has been a mature market since years.

India has been a reliable, technically competent, competitive and enterprising outsourcing option for many multinational companies in the field of Industrial Pumps and Systems for outsourcing.

- Pumps

- Systems

- Pump Components and sub-assemblies – cast and machined, fabricated and finished, moulded, customized and/or mass-produced

- Basic and applied, research and analysis employing also CFD techniques

- Resource persons for related activities like pump-design, surveying and auditing, repairs and maintenance services, etc.

Most Internationally well-known multinational pump companies have had technical collaborations and joint ventures in India for nearly four decades. Technical know-how of global standard has thus been well absorbed.

The traditional engineering skills of Indian experts are well-known. They have implemented in pattern-making, foundry practices, welding and fabrication, etc.

India has a vast pool of well-educated and technically qualified engineers and managers.

Computational skills of Indians and their fluency in English do merit specific mention, because these are important factors in the context of World Trade.

GLOBALISATION

It is about a decade by now that globalization of Indian economy became National Policy. There are different aspects to the Globalization of Indian economy –

- Growth of Indian economy with investments coming into India from around the world.

- Increasing presence of Indian products and services in the global market-place.

- Increasing presence of Indian Pump manufacturers in other countries thru’ JVs, Mergers and Acquisitions (M&As), apart from direct supply of Indian pumps and components to the markets in other countries.

PREVALENT MANUFACTURING STRATEGIES IN INDIAN PUMP INDUSTRY AND THEIR RELEVANCE TO WORLD PUMP MARKET

One sees both vertical and horizontal integrations in the manufacturing strategies being prevalent in Indian pump industry.

Vertical integration makes for diverse capital investments across all stages of manufacturing, from pattern-making, casting, machining, assembly, testing, painting and packing, dispatch and after-sales service of pumps. This helps to control process-costs and also better confidence of meeting delivery schedules. Also the enterprise can modulate the capital investments according to required scales of production.

Diversified outlay of capital investments also entails increased labour-strengths, supervisory costs, less flexibility in proportioning capacities to fluctuations in market demand.

Horizontal integration helps to have a diversified product-mix and better resilience to market-fluctuations in different market segments.

Many pump-manufacturers have ancillary suppliers serving as component vendors, even across different stages of manufacture. Pattern-makers, foundries, moulders, press-metal suppliers for stampings for motors, manufacturers of mechanical seals are typical categories of vendors to pump-manufacturers.

Foundry practices are prevalent across all types and scales and quality-demands for castings. Foundries do green-sand moulding, CO2 moulding, shell-moulding, lost-form or investment casting, gravity die casting, pressure die casting, etc. The metal-melting practices are also quite diverse ranging from crucible-melting, cupola-melting, to melting in arc furnaces and induction-melting. Castings are made in whole range of grades of metals ranging from grey cast iron, SG Irons, Ni-Resist and Ni-Hard Irons, Alloy steels, Stainless steels, Hastealloys, Monels, Bronzes, Aluminium-alloys, etc.

Global pump industry has been outsourcing components either cast or cast and proof-machined or cast and finished since many years, evidencing good faith in the satisfactory quality.

Global pump industry has also been outsourcing from India, pump-assemblies branded or unbranded, primarily made to their designs.

A recent example has been of an Indian pump-manufacturer, who was pump-supplier to a brand in a developed country for many years, for two-three decades in fact, evolved good enough for the foreign brand to willingly merge with Indian company.

There are also examples of multinational brands being much impressed with the work-culture and skills and caliber of the Indian Joint Venture partner that the multinational company acquired the Indian company.

Globalization of Indian economy offers to the world the whole array of outsourcing options for the global pump market.

PROSPECTS FOR INDIAN PUMP INDUSTRY IN THE GLOBAL MARKET

Globalization of Indian economy has brought forth the importance of the notable features of Indian Pump Industry in the global market. World Pump market is estimated to be of the order of US$ 45 billion by 2017.

More heartening is the fact that Indian pump industry is increasing its share in the World pump market. Indian pumps are being exported already to 70-odd countries around the world, covering both the developed and developing countries. “Made in India” brand is making forays into the global market with good credibility. This can be expected to happen increasingly and across many more countries around the world.

India has become a Business Process Outsourcing (BPO) hub for a variety of business activities, both of the hardware and software nature.

The hardware segment covers not only finished products like pumps, but also components and sub-assemblies.

ROLE OF IPMA

Almost all major manufacturers of pumps in India are members of IPMA, the apex body of Indian Pump Industry.

IPMA puts forth representations to the State Governments and to Central Government on issues, which affect pump industry at large.

IPMA always lends participation in Governmental programmes on issues of National concern.

IPMA and its members undertake preparing drafts for Indian Standards on pumps and motors and many other related topics. IPMA also actively participates in their finalization.

IPMA members voluntarily take licenses to mark their pumps with ISI mark, wherever applicable. IPMA members thereby demonstrate their commitment to quality and commitment on issues of National concern such as energy-conservation.

IPMA updates itself and disseminates awareness of the technological developments in the field of pumps through its journal and also by participating in exhibitions and trade-fairs and also by organizing National and International conferences on pumps.

IPMA keeps intimate interaction with global pump community and associations of pump manufacturers in countries around the world.

IPMA members are the major contributors in the country’s exports of pumps to the global market.

Ever since its inception in 1951, such has been the creed of IPMA that even though IPMA members are competitors in the market place, as IPMA, they are together on all issues of concern, which affect the Indian Pump Industry at large and also on all issues of National concern.

IPMA and its members help make the Indian Pump Industry grow and are more competent and competitive and in turn help the National economy grow and prosper.